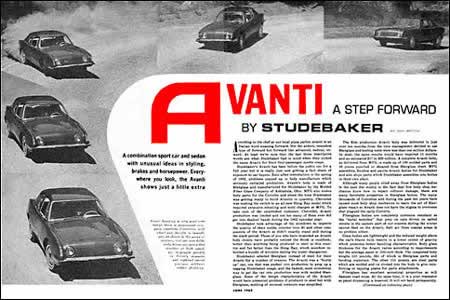

Opening spread in the June 1963 issue of Hot Rod Magazine.

June 1963 Hot Rod Magazine -

Avanti by Studebaker: A Step Forward

According to the chef at our local pizza parlor, avanti is an Italian word meaning forward. Not the ardent, immodest type of forward, but forward like advanced, radical, onward. At least we're sure that the last three descriptive words are what Studebaker had in mind when they picked the name Avanti for their four-passenger sports coupe. Studebaker's Avanti has been before the public eye for a full year but it is really just now getting a fair share of exposure to car buyers. Soon after introduction in the spring of 1962, problems popped up in body manufacture which seriously curtailed production. Avanti's body is made of fiberglass and manufactured for Studebaker by the Molded Fiber Glass Company of Ashtabula, Ohio. MFG also makes body parts for the Corvette and about the time Studebaker was getting ready to build Avantis in quantity, Chevrolet was making the switch to an all-new Sting Ray model which required extensive retooling and mold changes at MFG.

To take care of the established customer, Chevrolet, Avanti production was limited and not too many of them ever did get into dealers' hands during the 1962 calendar year. Studebaker took advantage of the slowdown to improve the quality of their molds, interior trim fit and other components of the Avanti so didn't exactly stand still during the slack period. Those of you who have inspected an Avanti body closely have probably noticed the finish is excellent; better than anything being produced in steel in this country and far better than the Sting Ray, which somehow inherited a bundle of wrinkles during the model changeover.

Studebaker selected fiberglass instead of steel for their Avanti for a number of reasons. The Avanti was s "hurry up" car, one that was pushed into production to prop up a sagging Studebaker image, and the fastest, most economical way to get the car into production was with molded fiberglass. Some of the design characteristics of the Avanti would have presented problems if produced in steel but with fiberglass, molding of unusual contours was simplified. The first production Avanti body was delivered in just over ten months from the time management decided to use fiberglass and tooling costs were less than one million dollars. In steel, the same results would have required 15 months and an estimated $17 to $20 million. A complete Avanti body, as delvered from MFG, is made up of 100 molded parts and 36 pieces punched or sheared from fiberglass sheet. MFG assembles, finishes and paints Avanti bodies for Studebaker and also ships parts which Studebaker assembles into bodies in their own plant. Although many people shied away from fiberglass bodies in the past due mostly to the fact that few body shop mechanics knew how to repair collision damage, their are many favorable properties in fiberglass bodies. The many thousands of Corvettes sold during the past ten years have caused most body shop mechanics to learn the art of fiberglass repair so Avanti does not have the stigma to overcome that plagued the early Corvette. Fiberglass bodies are completely corrosion resistant so the "metal termites" that prey on cars driven on salted streets in the eastern part of our country during the winter cannot feed on the Avanti. Salt air from coastal areas is no problem either. Glass bodies are lightweight and the reduced weight above the car's frame rails results in a lower center of gravity which promotes better handling characteristics.

Body glass thickness for the Avanti varies according to requirements but the average panel is .100-inch thick. The completed body weighs 510 pounds, 355 of which is fiberglass parts and bonding materials. The other 155 pounds are steel parts which are molded and/or riveted into the body to give reinforcing or tapping plates for parts attachments. Fiberglass has excellent acoustical properties so will dampen road noise. At the same time, it is a poor resonator so panel drumming is lessened. It will not bend permanently. It will flex and return to its original shape even after substantial abuse so many body and fender bumps sustained by the average steel car would appear only as scratched paint on a fiberglass body. An extreme blow will of course fracture fiberglass and require repair. Fiberglass cannot be bent or scratched like sheet metal so fits between doors, hoods, trunk lids and their openings must be much more accurate than with a metal body. It is impossible to jack or hammer a glass body and door to change fit. They must fit right from the mold. A whole story could be written on the Avanti's fiberglass body but the best way to understand the precision used in their manufacture is to inspect one closely. Note that there are no chrome strips used on the body. None are needed since the entire body, minus hood, doors, trunk lid and gass filler door, is finished into one piece. All body joints are filled and smoothed so that chrome is not needed to cover joints.

Progressing to the interior of the Avanti, it is distinctive with styling resembling an airplane cockpit. Instruments are grouped directly in front of the driver and except for the windshield wiper control and ignition lock, all switches are in a small panel grouping centered above the windshield. Easy-to-read instruments tell the driver what's going on under the hood and how fast he's covering ground. An electric tachometer is standard equipment and has a wide-sweep dial to 6000 rpm. The speedometer is calibrated to 160 mph. Three smaller intruments mount to either side of the tach and speedometer; clock, water temperature and ammeter to the left; gasoline, oil pressure and vacuum-pressure gage to the right. The instrument panel is recessed well into the padded dash so that no instrument light glare reaches the windshield in night driving. A console unit fits between the bucket seats up front and contains aircraft-style levers for air vent, temperature and heater controls at the forward end. Next in line is the shift lever, either automatic or manual, then ash tray with lighter, and last, a secondary glove box of fairly small dimensions. The console does not extend into the rear seat area although there is a medium sized drive-shaft tunnel in that area.

Seating in the Avanti's front seats is comfortable despite the fact that they are rather close to the floor as dictated by the low body lines. They are really the nearest thing to a true bucket seat being built by an American manufacturer. The seat shell, both back and bottom, is fiberglass with only the hinges and seat track attaching plates metal. The vinyl upholstery is shaped to wrap around the occupants back side snugly and even though we are personally of rather generous proportions, we found seating comfortable. The seat bottom is divided so that the center part of the cushion sinks to absorb body weight, while the rolled side sections do not deflect but stay firm to restrict a person from sliding on tight corners. The back seat is a compromise between buckets and bench type and although not as comfortable as the front seats and more restricted on head and leg room, the rear seats will hold a pair of large adults without complaints from them. Entry into the rear seat is eased somewhat by the fact that the front seats fold far forward and the doors are very wide, opening partially into the rear compartment. A comforting feature for Avanti passengers is the built-in roll bar which passes across the top between front and rear seats. This stamped steel section acts also as the post between door and rear side windows, and ties into a reinforced section in the rocker panel. It is a sturdy member and although it extends below the top shell, it is well padded for the safety of entering or exiting rear set passengers. Although interior appointments, like styling, are a matter of a person's individual tastes, we found little to criticize in the Avanti. One exception was the ridiculously small rear view mirror. One about four times the size would be just right. Front seat ventilation could be better too although we did eventually work out a fairly good way to cool the Avanti on warm days. By opening the two swing-out rear side windows to their limit, then opening all cowl vents, including defroster (hot water valve off), and leaving door glass and vent windows closed, we could create circulation through the cowl air intakes and out the back windows. It is no substitute for air conditioning but it is better than being buffeted by wind through the door glass on a hot day.

Although the Avanti is not a small car, it isn't particularly big either. The car which it most closely approximates (except for length) is the Falcon. The Avanti uses a 109-inch wheelbase (1/2 inch less than Falcon), is about 70 inches wide (same), 54 inches high (same) and 192 1/2 inches long (almost a foot more than Falcon). Avanti tread is 57 1/2 front and 56 1/2 rear. The Avanti uses a modified Lark convertible frame and standard Studebaker suspension components. The X-member convertible frame has 160% more rigidity than the ladder-type Lark frame and when compared to a standard Lark hardtop with steel body, the Avanti body and frame give a 49% increase in total unit rigidity. Even with the heavier X-member frame, weight savings with the fiberglass body make the Avanti body-frame combination 166 pounds lighter than a Lark hardtop body-frame. Also, the Avanti center of gravity is far lower than the Lark's.

Although the Avant's suspension components are basically standard Studebaker, modifications and extras have been instituted here too. Front suspension is by unequal length A-arms with coil springs. A stabilizer bar clamps to the lower A-arm on each side with the center portion of the bar suspended from the forward frame extensions by links. Adjustable Gabriel tubular shocks are used inside the coil springs. Studebaker is one of the few American built cars we can think of which does not use ball-joints on their front suspension. Instead, the spindle support acts as a king-pin, passing through spindle bushings and fastening to a forged steel extension on the lower control arm. The whole set-up looks quite sturdy and should give excellent service before requiring new bushings. Suspension at the rear is by conventional semi-elliptic 5-leaf springs and a Spicer type rear axle. Additional features for the Avanti are radius rods that fit between brackets on the axle housing and frame on each side of the car. These rods fit above the axle so do not restrict ground clearance. Their purpose is to prevent "dive" on hard braking and "squat" on acceleration that often accompanies a light-duty leaf spring. Another Avanti extra is a stabilizer bar with ends attached to bushings on the spring clip plates and the center part linked to frame brackets behind the rear axle. As at the front, adjustable Gabriel tube shocks are used. Ride is firm by most standards and a stiffer heavy-duty suspension is an available option.

Steering for the Avanti is standard Studebaker with a drag link extending forward from the pitman arm to a bell-crank idler bracketed to the crossmember under the front of the engine. A pair of tie-rod links extend from this central steering pivot to outer steering arms at the spindle. The standard steering gear has an overall ratio of 24.5:1 with 5 turns of the steering wheel required lock-to-lock. An optional link-type power steering unit has an overall ratio of 18:1, 3 1/2 turns lock-to-lock.

As with many other features on the Avanti, something a little extra has been added in the brake department. Instead of the usual drum brakes both front and rear, Bendix disc brakes are fitted to front wheels, special heavy-duty cast iron drums to the rear wheels. These disc units were engineered by Dunlop of England with Bendix licensed to make them here. Each unit consists of a cast iron caliper with housings which bolt to either side and contain 2 1/8-inch hydraulic cylinders to force 2-inch square pucks against either side of an 11 1/2-inch cast iron disc. The caliper is fastened to the spindle forging and a sheet metal dust cover fits over the inner side of the disc. These disc brakes have several distinct advantages over drum brakes and although there's been a lot of talk about them in this country for years, the main reason why they haven't reached a production status before is mostly a matter of high cost. Disc brakes are unaffected by water, mud or other foreign matter and have excellent fade resistant qualities since only a small portion of the disc is actually clamped between the lining segments at any one time while the rest of the disc is exposed to cooling air. Brake "pull" against steering is non-existent with discs making straight-line stops every time. Disadvantages, other than cost, for the most part concern high line pressure to operate the wheel cylinders since linings are not self-energizing. Power assist takes care of this. Also, parking brake attachments on disc brakes are complicated but Studebaker solved this quite simply by using their drum brakes with parking brake linkage on the rear. The combination of disc front and drum rear works very well since the discs are designed to take 62% of the breaking load. The heavy-duty cast iron drums on the rear have wide flanges which extend into the air stream to dissipate heat and prevent "bellmouth" drums under high heat. They are 11 inches in diameter with 2-inch lining. To compliment the highly effective braking system on the Avanti, 15-inch wheels are standard so that air flow over brake components is substantial to air cooling. Power brakes are standard on the Avanti. During all the test driving we did with the Avanti, and it was considerable, we never experienced any brake fade or erratic behavior. Even after high speed runs at both 1/4- and 1/2-mile drag meets, we could stop as quickly as we wanted. Even with power assist, they are not "touchy." If you really use them hard, stops can be made in an unbelievably short distance without wheel slide. Avanti brakes rate A-plus by standards in this country.

There are three engines available in the Avanti and they are designated R1, R2 and R3. Studebaker does not advertise power ratings of the Avanti engines, they just say that the engine has all the power a driver can use. Well, they may think so but a performance-minded buyer still likes to have a horsepower figure to mull over when he chooses a car. And, the Avanti is supposed to appeal to performance enthusiasts so since Stude won't put a power tag on the three engines, we'll make our own guesses. The R1 and R2 engines are both 289 cubic inches displacement and the R1 is the standard powerplant for Avantis. It has 10.25:1 compression, a 260 mechanical lifter camshaft and single four-barrel carburetion. We will guess its output at 240 hp. The R2, although the same displacement and fitted with the same camshaft as the R1, has less compression, 9:1, has a four-barrel carburetor and gets an assist from a belt-driven Paxton centrifugal supercharger. This supercharger produces a maximum of 5 pounds boost in the intake manifold at 5200 rpm. We'll guess its horsepower at about 285 with full boost pressure. The optional R2 engine lists for $210 extra. The top engine option is called the R3. In its early development form, this R3 engine had 299 inches displacement but as released to the public, it will have 3/32-inch larger bore than the 289's for a 3 21/32 which with the 3 5/8-inch 289 stroke, gives 304.5 cubic inches. It has a camshaft with more duration, 9.5:1 compression, improved heads, a four-barrel carburetor and a Paxton supercharger with 6 pounds manifold boost at 5200 rpm. The R3 we'll give a rating of about 305 horsepower but there's more here than meets the eye. R3 engines are built by Paxton Products in Santa Monica and they are hand built to rigid specifications. Cylinder blocks as received from Studebaker in South Bend, are standard 289 items. First, Paxton bores them to the 304-inch bore size, then the top of each cylinder bore is machined to give a pair of notches for valve clearance and to match the chamber shape in the heads. Last, block height from the main bearing bores is carefully checked and the block surfaced on each bank to ensure exact alignment and clearance between piston and deck.

Standard forged steel crankshafts are used but heavy-duty aluminum bearing inserts are used for both mains and rods. The pistons are made by Forged-true and have a flat top with no valve reliefs or pop-up section. Cylinder heads for the R3 are special castings and have larger-than-standard port areas. Valves are 1/8-inch larger than those used on the R1 and R2 heads. Intakes are 1 3/4-inch and exhausts are 1 5/8-inch. Also, the valves are undercut and polished. Chambers for R3 cylinder heads are first machined to give uniform shape and volume, then hand polished to eliminate all sharp edges. With uniform chamber volume and deck clearances, all R3 engines will be quite close to their designed 9.5:1 ratio. The camshaft used in the R3 is more radical than that used in the other R-engines but it is by no means "wild" when compared to the ones used by most of the high performance engines on the market. It has 272 duration while most of the big 400-plus-inchers have around 300 duration. A large-runner aluminum intake manifold tops the R3 with a single four-barrel carburetor enclosed in a cast aluminum pressure box. Different blower pulley ratios are used on the R3 and it is supposed to deliver 6 pounds boost at 5200 rpm. Now although we've estimated a horsepower figure of 305 for the R3 engine, we've based that guess on 6 pounds boost at 5200 rpm. The pressure build-up is pretty rapid in a centrifugal supercharger at high rpm's and we wouldn't be a bit surprised if an accurate gage would show about 8 pounds at 6000 and maybe even 11 or 12 pounds at 6500 rpm. Guessing horsepower gets a little ridiculous but we drove an R3 Avanti in some timed drag events and registered speeds that would only be possible if the engine produced at least 325 horsepower, maybe much more.

All told, we spent time behind the wheels of three Avantis while gathering information for this report. Our first car was a production R2 with optional four-speed transmission. Next was a Studebaker Engineering prototype R3 with automatic transmission. The last car, and the one which we put the most mileage on (over 1000 miles) was a late production R2 with automatic. We picked it up brand new before it had even had new car detailing and when we returned it, the only notation we had made for the dealer was that there was a slight exhaust leak somewhere.

The first R2 with four-speed and standard 3.73 rear axle ratio turned an even 90 mph in the 1/4-mile and had a 16-second elapsed time. Not too outstanding but then not too bad considering gearing and a small engine with limited blower pressure. The next Avanti was the R3 version, hottest thing made by Studebaker, and it was a surpriser. Out first outing with the R3 was at a drag meet using the back stretch of the Riverside International Raceway. The sponsoring Southern California Timing Association conducts occasional 1/2-mile drags on this long stretch. We had the prototype 299-inch R3 for this meet and a 4.09 rear axle ratio. Regular 6.70 x 15 street tires were fitted. The transmission was Studebaker's automatic made by Borg-Warner with ratios of 2.40, 1.47 and 1:1. On our first run, we found that the Avanti would not take off from the line in sensational fashion due to the relatively small displacement and the fact that blower boost does not really come on strong until the engine reaches about 3000 rpm. No matter how we tried driving the car, starts were slow. But, once the engine got above 3000 rpm, it started to move and felt very strong. We made the 1-2 shift at 6200 but engine acceleration was so rapid that the tach touched 7000 just as the automatic shifted. Again, the 2-3 shift was made at 6200 and this time the action was quicker with the tach reaching about 6500. At the end of the half-mile, the tach showed 6700. We made several runs during the day, changed to larger street tires, changed plugs and tried several driving styles. The best results were 128.94 mph and 21.30 seconds elapsed time. SCTA uses only speed for their half-mile records and we discovered that the Avanti had raised the class record by almost 6 mph. As a comparative figure, the hottest Super Stocker time recorded in the half was 136 mph by a 426 Plymouth.

The following weekend, we took the same car to Pomona for a try at the quarter-mile. A 4.89 rear axle ratio had been installed for the shorter track. The first run netted a speed of 107.78 mph and an elapsed time of 13.71. The next run was almost identical. The engine was well over its peak at the end of the quarter and the tach showed 7000 through the lights so we decoded to put on some larger tires we had brought along. After we arrived back at the pits, we discovered that the alternator belt had flipped off on the run just completed and passed between the dual blower belts and their idler, breaking a bracket on the idler tensioner. So, we were out of racing business for the day. Had we been able to run the larger tires, we are confident that speed would have been close to 110 mph and we should have been able to work the elapsed time down in the low 13's. All of the runs, both 1/2-mile and 1/4-mile, were made with stock exhaust system (loud though) and air cleaner. Even with the belts off and blower inoperative, the Avanti can be driven. We drove about 100 miles before we got back to Paxton Products for repairs.

The last test car we used was the new R2 and we made no attempt to try it at the drags. We just drove it and enjoyed it. A few short bursts through the gears in remote locations proved that it had adequate power, as Studebaker claims. Even with the blower, the engine is very smooth, quiet and docile as a limousine in heavy traffic. Amazingly enough, we used the R3 version in our travels to and from the office and except for the objectionable gear ratio we had fitted for the drags, it too was a very smooth car for daily duties. Admittedly, we used the new R2 pretty well whenever opportunity permitted after we got the first few hundred miles on the engine, but even with our heavy foot, we never got worse than 12 miles per gallon. We wouldn't hesitate to bet that a careful driver could get 16 mpg at a steady highway pace with an R2 Avanti. Andy Granatelli, President of Studebaker's Paxton Division, prepared several cars to make USAC-sanctioned record attempts at Bonneville late last winter and although most of the trials were frozen out by bad weather, he did manage to make some official two-way averages with a Lark, a Hawk and an Avanti, all equipped with R2 engines and four-speed transmissions. The cars were completely stock including exhausts. Naturally, they were tuned to the highest degree. The Lark averaged 132.04 mph. The Hawk, with its sleeker body lines, averaged 140.24 mph. The Avanti, a real slippery customer in the aerodynamics department, averaged 158.14 mph through the flying mile. With everything else equal, it proves how important body shape can be. Even on the highway, the smooth lines of the Avanti show up in reduced wind noise at high speeds. It is a very quiet car.

Speaking of driving the Avanti on the highway, the more twisting the highway becomes, the more fun this car is to drive. Our R2 with automatic weighed 3590 pounds full of fuel but minus passengers. 56% of this weight rests on the front wheels but every passenger you add improves the balance between front and rear. 62% of front seat passenger weight goes on the rear wheels, only 38% to the front. Rear seat passengers donate 80% of their body weight to the rear wheels. Even with just the driver, Avanti handling is great. It might take some getting used to a car with heavy under steer because this car is just the opposite; it has a lot of over steer and the tail end of the Avanti swings out quickly when taken through sharp corners fast. Just pour the power on and you can direct the car anyplace you want to go in the corner. The over steer gives the front end a light, easily controllable feel and the throttle takes care of the rear.

On the opening pages of this story, you'll see a series of pictures where we played around with the Avanti on a sharp uphill corner on a narrow mountain road. We drove the car into the corner very fast and then purposely "tossed" the rear wheels off onto the graded dirt shoulder to test control. By using plenty of power and correcting into the slide, we easily maintained control and pulled back onto the pavement and on up the road. We can't think of any other sedan we'd care to try this trick with. The Avanti has a handling style all its own but with just a little practice, driving one on twisting roads can be thrilling. Summing up our experiences with the Avanti, we must admit that we were won over. We didn't think we'd be too impressed but body quality, the power of the R3 engine, handling and other . . .

Studebaker selected fiberglass instead of steel for their Avanti for a number of reasons. The Avanti was s "hurry up" car, one that was pushed into production to prop up a sagging Studebaker image, and the fastest, most economical way to get the car into production was with molded fiberglass. Some of the design characteristics of the Avanti would have presented problems if produced in steel but with fiberglass, molding of unusual contours was simplified. The first production Avanti body was delivered in just over ten months from the time management decided to use fiberglass and tooling costs were less than one million dollars. In steel, the same results would have required 15 months and an estimated $17 to $20 million. A complete Avanti body, as delvered from MFG, is made up of 100 molded parts and 36 pieces punched or sheared from fiberglass sheet. MFG assembles, finishes and paints Avanti bodies for Studebaker and also ships parts which Studebaker assembles into bodies in their own plant. Although many people shied away from fiberglass bodies in the past due mostly to the fact that few body shop mechanics knew how to repair collision damage, their are many favorable properties in fiberglass bodies. The many thousands of Corvettes sold during the past ten years have caused most body shop mechanics to learn the art of fiberglass repair so Avanti does not have the stigma to overcome that plagued the early Corvette. Fiberglass bodies are completely corrosion resistant so the "metal termites" that prey on cars driven on salted streets in the eastern part of our country during the winter cannot feed on the Avanti. Salt air from coastal areas is no problem either. Glass bodies are lightweight and the reduced weight above the car's frame rails results in a lower center of gravity which promotes better handling characteristics.

Body glass thickness for the Avanti varies according to requirements but the average panel is .100-inch thick. The completed body weighs 510 pounds, 355 of which is fiberglass parts and bonding materials. The other 155 pounds are steel parts which are molded and/or riveted into the body to give reinforcing or tapping plates for parts attachments. Fiberglass has excellent acoustical properties so will dampen road noise. At the same time, it is a poor resonator so panel drumming is lessened. It will not bend permanently. It will flex and return to its original shape even after substantial abuse so many body and fender bumps sustained by the average steel car would appear only as scratched paint on a fiberglass body. An extreme blow will of course fracture fiberglass and require repair. Fiberglass cannot be bent or scratched like sheet metal so fits between doors, hoods, trunk lids and their openings must be much more accurate than with a metal body. It is impossible to jack or hammer a glass body and door to change fit. They must fit right from the mold. A whole story could be written on the Avanti's fiberglass body but the best way to understand the precision used in their manufacture is to inspect one closely. Note that there are no chrome strips used on the body. None are needed since the entire body, minus hood, doors, trunk lid and gass filler door, is finished into one piece. All body joints are filled and smoothed so that chrome is not needed to cover joints.

Progressing to the interior of the Avanti, it is distinctive with styling resembling an airplane cockpit. Instruments are grouped directly in front of the driver and except for the windshield wiper control and ignition lock, all switches are in a small panel grouping centered above the windshield. Easy-to-read instruments tell the driver what's going on under the hood and how fast he's covering ground. An electric tachometer is standard equipment and has a wide-sweep dial to 6000 rpm. The speedometer is calibrated to 160 mph. Three smaller intruments mount to either side of the tach and speedometer; clock, water temperature and ammeter to the left; gasoline, oil pressure and vacuum-pressure gage to the right. The instrument panel is recessed well into the padded dash so that no instrument light glare reaches the windshield in night driving. A console unit fits between the bucket seats up front and contains aircraft-style levers for air vent, temperature and heater controls at the forward end. Next in line is the shift lever, either automatic or manual, then ash tray with lighter, and last, a secondary glove box of fairly small dimensions. The console does not extend into the rear seat area although there is a medium sized drive-shaft tunnel in that area.

Seating in the Avanti's front seats is comfortable despite the fact that they are rather close to the floor as dictated by the low body lines. They are really the nearest thing to a true bucket seat being built by an American manufacturer. The seat shell, both back and bottom, is fiberglass with only the hinges and seat track attaching plates metal. The vinyl upholstery is shaped to wrap around the occupants back side snugly and even though we are personally of rather generous proportions, we found seating comfortable. The seat bottom is divided so that the center part of the cushion sinks to absorb body weight, while the rolled side sections do not deflect but stay firm to restrict a person from sliding on tight corners. The back seat is a compromise between buckets and bench type and although not as comfortable as the front seats and more restricted on head and leg room, the rear seats will hold a pair of large adults without complaints from them. Entry into the rear seat is eased somewhat by the fact that the front seats fold far forward and the doors are very wide, opening partially into the rear compartment. A comforting feature for Avanti passengers is the built-in roll bar which passes across the top between front and rear seats. This stamped steel section acts also as the post between door and rear side windows, and ties into a reinforced section in the rocker panel. It is a sturdy member and although it extends below the top shell, it is well padded for the safety of entering or exiting rear set passengers. Although interior appointments, like styling, are a matter of a person's individual tastes, we found little to criticize in the Avanti. One exception was the ridiculously small rear view mirror. One about four times the size would be just right. Front seat ventilation could be better too although we did eventually work out a fairly good way to cool the Avanti on warm days. By opening the two swing-out rear side windows to their limit, then opening all cowl vents, including defroster (hot water valve off), and leaving door glass and vent windows closed, we could create circulation through the cowl air intakes and out the back windows. It is no substitute for air conditioning but it is better than being buffeted by wind through the door glass on a hot day.

Although the Avanti is not a small car, it isn't particularly big either. The car which it most closely approximates (except for length) is the Falcon. The Avanti uses a 109-inch wheelbase (1/2 inch less than Falcon), is about 70 inches wide (same), 54 inches high (same) and 192 1/2 inches long (almost a foot more than Falcon). Avanti tread is 57 1/2 front and 56 1/2 rear. The Avanti uses a modified Lark convertible frame and standard Studebaker suspension components. The X-member convertible frame has 160% more rigidity than the ladder-type Lark frame and when compared to a standard Lark hardtop with steel body, the Avanti body and frame give a 49% increase in total unit rigidity. Even with the heavier X-member frame, weight savings with the fiberglass body make the Avanti body-frame combination 166 pounds lighter than a Lark hardtop body-frame. Also, the Avanti center of gravity is far lower than the Lark's.

Although the Avant's suspension components are basically standard Studebaker, modifications and extras have been instituted here too. Front suspension is by unequal length A-arms with coil springs. A stabilizer bar clamps to the lower A-arm on each side with the center portion of the bar suspended from the forward frame extensions by links. Adjustable Gabriel tubular shocks are used inside the coil springs. Studebaker is one of the few American built cars we can think of which does not use ball-joints on their front suspension. Instead, the spindle support acts as a king-pin, passing through spindle bushings and fastening to a forged steel extension on the lower control arm. The whole set-up looks quite sturdy and should give excellent service before requiring new bushings. Suspension at the rear is by conventional semi-elliptic 5-leaf springs and a Spicer type rear axle. Additional features for the Avanti are radius rods that fit between brackets on the axle housing and frame on each side of the car. These rods fit above the axle so do not restrict ground clearance. Their purpose is to prevent "dive" on hard braking and "squat" on acceleration that often accompanies a light-duty leaf spring. Another Avanti extra is a stabilizer bar with ends attached to bushings on the spring clip plates and the center part linked to frame brackets behind the rear axle. As at the front, adjustable Gabriel tube shocks are used. Ride is firm by most standards and a stiffer heavy-duty suspension is an available option.

Steering for the Avanti is standard Studebaker with a drag link extending forward from the pitman arm to a bell-crank idler bracketed to the crossmember under the front of the engine. A pair of tie-rod links extend from this central steering pivot to outer steering arms at the spindle. The standard steering gear has an overall ratio of 24.5:1 with 5 turns of the steering wheel required lock-to-lock. An optional link-type power steering unit has an overall ratio of 18:1, 3 1/2 turns lock-to-lock.

As with many other features on the Avanti, something a little extra has been added in the brake department. Instead of the usual drum brakes both front and rear, Bendix disc brakes are fitted to front wheels, special heavy-duty cast iron drums to the rear wheels. These disc units were engineered by Dunlop of England with Bendix licensed to make them here. Each unit consists of a cast iron caliper with housings which bolt to either side and contain 2 1/8-inch hydraulic cylinders to force 2-inch square pucks against either side of an 11 1/2-inch cast iron disc. The caliper is fastened to the spindle forging and a sheet metal dust cover fits over the inner side of the disc. These disc brakes have several distinct advantages over drum brakes and although there's been a lot of talk about them in this country for years, the main reason why they haven't reached a production status before is mostly a matter of high cost. Disc brakes are unaffected by water, mud or other foreign matter and have excellent fade resistant qualities since only a small portion of the disc is actually clamped between the lining segments at any one time while the rest of the disc is exposed to cooling air. Brake "pull" against steering is non-existent with discs making straight-line stops every time. Disadvantages, other than cost, for the most part concern high line pressure to operate the wheel cylinders since linings are not self-energizing. Power assist takes care of this. Also, parking brake attachments on disc brakes are complicated but Studebaker solved this quite simply by using their drum brakes with parking brake linkage on the rear. The combination of disc front and drum rear works very well since the discs are designed to take 62% of the breaking load. The heavy-duty cast iron drums on the rear have wide flanges which extend into the air stream to dissipate heat and prevent "bellmouth" drums under high heat. They are 11 inches in diameter with 2-inch lining. To compliment the highly effective braking system on the Avanti, 15-inch wheels are standard so that air flow over brake components is substantial to air cooling. Power brakes are standard on the Avanti. During all the test driving we did with the Avanti, and it was considerable, we never experienced any brake fade or erratic behavior. Even after high speed runs at both 1/4- and 1/2-mile drag meets, we could stop as quickly as we wanted. Even with power assist, they are not "touchy." If you really use them hard, stops can be made in an unbelievably short distance without wheel slide. Avanti brakes rate A-plus by standards in this country.

There are three engines available in the Avanti and they are designated R1, R2 and R3. Studebaker does not advertise power ratings of the Avanti engines, they just say that the engine has all the power a driver can use. Well, they may think so but a performance-minded buyer still likes to have a horsepower figure to mull over when he chooses a car. And, the Avanti is supposed to appeal to performance enthusiasts so since Stude won't put a power tag on the three engines, we'll make our own guesses. The R1 and R2 engines are both 289 cubic inches displacement and the R1 is the standard powerplant for Avantis. It has 10.25:1 compression, a 260 mechanical lifter camshaft and single four-barrel carburetion. We will guess its output at 240 hp. The R2, although the same displacement and fitted with the same camshaft as the R1, has less compression, 9:1, has a four-barrel carburetor and gets an assist from a belt-driven Paxton centrifugal supercharger. This supercharger produces a maximum of 5 pounds boost in the intake manifold at 5200 rpm. We'll guess its horsepower at about 285 with full boost pressure. The optional R2 engine lists for $210 extra. The top engine option is called the R3. In its early development form, this R3 engine had 299 inches displacement but as released to the public, it will have 3/32-inch larger bore than the 289's for a 3 21/32 which with the 3 5/8-inch 289 stroke, gives 304.5 cubic inches. It has a camshaft with more duration, 9.5:1 compression, improved heads, a four-barrel carburetor and a Paxton supercharger with 6 pounds manifold boost at 5200 rpm. The R3 we'll give a rating of about 305 horsepower but there's more here than meets the eye. R3 engines are built by Paxton Products in Santa Monica and they are hand built to rigid specifications. Cylinder blocks as received from Studebaker in South Bend, are standard 289 items. First, Paxton bores them to the 304-inch bore size, then the top of each cylinder bore is machined to give a pair of notches for valve clearance and to match the chamber shape in the heads. Last, block height from the main bearing bores is carefully checked and the block surfaced on each bank to ensure exact alignment and clearance between piston and deck.

Standard forged steel crankshafts are used but heavy-duty aluminum bearing inserts are used for both mains and rods. The pistons are made by Forged-true and have a flat top with no valve reliefs or pop-up section. Cylinder heads for the R3 are special castings and have larger-than-standard port areas. Valves are 1/8-inch larger than those used on the R1 and R2 heads. Intakes are 1 3/4-inch and exhausts are 1 5/8-inch. Also, the valves are undercut and polished. Chambers for R3 cylinder heads are first machined to give uniform shape and volume, then hand polished to eliminate all sharp edges. With uniform chamber volume and deck clearances, all R3 engines will be quite close to their designed 9.5:1 ratio. The camshaft used in the R3 is more radical than that used in the other R-engines but it is by no means "wild" when compared to the ones used by most of the high performance engines on the market. It has 272 duration while most of the big 400-plus-inchers have around 300 duration. A large-runner aluminum intake manifold tops the R3 with a single four-barrel carburetor enclosed in a cast aluminum pressure box. Different blower pulley ratios are used on the R3 and it is supposed to deliver 6 pounds boost at 5200 rpm. Now although we've estimated a horsepower figure of 305 for the R3 engine, we've based that guess on 6 pounds boost at 5200 rpm. The pressure build-up is pretty rapid in a centrifugal supercharger at high rpm's and we wouldn't be a bit surprised if an accurate gage would show about 8 pounds at 6000 and maybe even 11 or 12 pounds at 6500 rpm. Guessing horsepower gets a little ridiculous but we drove an R3 Avanti in some timed drag events and registered speeds that would only be possible if the engine produced at least 325 horsepower, maybe much more.

All told, we spent time behind the wheels of three Avantis while gathering information for this report. Our first car was a production R2 with optional four-speed transmission. Next was a Studebaker Engineering prototype R3 with automatic transmission. The last car, and the one which we put the most mileage on (over 1000 miles) was a late production R2 with automatic. We picked it up brand new before it had even had new car detailing and when we returned it, the only notation we had made for the dealer was that there was a slight exhaust leak somewhere.

The first R2 with four-speed and standard 3.73 rear axle ratio turned an even 90 mph in the 1/4-mile and had a 16-second elapsed time. Not too outstanding but then not too bad considering gearing and a small engine with limited blower pressure. The next Avanti was the R3 version, hottest thing made by Studebaker, and it was a surpriser. Out first outing with the R3 was at a drag meet using the back stretch of the Riverside International Raceway. The sponsoring Southern California Timing Association conducts occasional 1/2-mile drags on this long stretch. We had the prototype 299-inch R3 for this meet and a 4.09 rear axle ratio. Regular 6.70 x 15 street tires were fitted. The transmission was Studebaker's automatic made by Borg-Warner with ratios of 2.40, 1.47 and 1:1. On our first run, we found that the Avanti would not take off from the line in sensational fashion due to the relatively small displacement and the fact that blower boost does not really come on strong until the engine reaches about 3000 rpm. No matter how we tried driving the car, starts were slow. But, once the engine got above 3000 rpm, it started to move and felt very strong. We made the 1-2 shift at 6200 but engine acceleration was so rapid that the tach touched 7000 just as the automatic shifted. Again, the 2-3 shift was made at 6200 and this time the action was quicker with the tach reaching about 6500. At the end of the half-mile, the tach showed 6700. We made several runs during the day, changed to larger street tires, changed plugs and tried several driving styles. The best results were 128.94 mph and 21.30 seconds elapsed time. SCTA uses only speed for their half-mile records and we discovered that the Avanti had raised the class record by almost 6 mph. As a comparative figure, the hottest Super Stocker time recorded in the half was 136 mph by a 426 Plymouth.

The following weekend, we took the same car to Pomona for a try at the quarter-mile. A 4.89 rear axle ratio had been installed for the shorter track. The first run netted a speed of 107.78 mph and an elapsed time of 13.71. The next run was almost identical. The engine was well over its peak at the end of the quarter and the tach showed 7000 through the lights so we decoded to put on some larger tires we had brought along. After we arrived back at the pits, we discovered that the alternator belt had flipped off on the run just completed and passed between the dual blower belts and their idler, breaking a bracket on the idler tensioner. So, we were out of racing business for the day. Had we been able to run the larger tires, we are confident that speed would have been close to 110 mph and we should have been able to work the elapsed time down in the low 13's. All of the runs, both 1/2-mile and 1/4-mile, were made with stock exhaust system (loud though) and air cleaner. Even with the belts off and blower inoperative, the Avanti can be driven. We drove about 100 miles before we got back to Paxton Products for repairs.

The last test car we used was the new R2 and we made no attempt to try it at the drags. We just drove it and enjoyed it. A few short bursts through the gears in remote locations proved that it had adequate power, as Studebaker claims. Even with the blower, the engine is very smooth, quiet and docile as a limousine in heavy traffic. Amazingly enough, we used the R3 version in our travels to and from the office and except for the objectionable gear ratio we had fitted for the drags, it too was a very smooth car for daily duties. Admittedly, we used the new R2 pretty well whenever opportunity permitted after we got the first few hundred miles on the engine, but even with our heavy foot, we never got worse than 12 miles per gallon. We wouldn't hesitate to bet that a careful driver could get 16 mpg at a steady highway pace with an R2 Avanti. Andy Granatelli, President of Studebaker's Paxton Division, prepared several cars to make USAC-sanctioned record attempts at Bonneville late last winter and although most of the trials were frozen out by bad weather, he did manage to make some official two-way averages with a Lark, a Hawk and an Avanti, all equipped with R2 engines and four-speed transmissions. The cars were completely stock including exhausts. Naturally, they were tuned to the highest degree. The Lark averaged 132.04 mph. The Hawk, with its sleeker body lines, averaged 140.24 mph. The Avanti, a real slippery customer in the aerodynamics department, averaged 158.14 mph through the flying mile. With everything else equal, it proves how important body shape can be. Even on the highway, the smooth lines of the Avanti show up in reduced wind noise at high speeds. It is a very quiet car.

Speaking of driving the Avanti on the highway, the more twisting the highway becomes, the more fun this car is to drive. Our R2 with automatic weighed 3590 pounds full of fuel but minus passengers. 56% of this weight rests on the front wheels but every passenger you add improves the balance between front and rear. 62% of front seat passenger weight goes on the rear wheels, only 38% to the front. Rear seat passengers donate 80% of their body weight to the rear wheels. Even with just the driver, Avanti handling is great. It might take some getting used to a car with heavy under steer because this car is just the opposite; it has a lot of over steer and the tail end of the Avanti swings out quickly when taken through sharp corners fast. Just pour the power on and you can direct the car anyplace you want to go in the corner. The over steer gives the front end a light, easily controllable feel and the throttle takes care of the rear.

On the opening pages of this story, you'll see a series of pictures where we played around with the Avanti on a sharp uphill corner on a narrow mountain road. We drove the car into the corner very fast and then purposely "tossed" the rear wheels off onto the graded dirt shoulder to test control. By using plenty of power and correcting into the slide, we easily maintained control and pulled back onto the pavement and on up the road. We can't think of any other sedan we'd care to try this trick with. The Avanti has a handling style all its own but with just a little practice, driving one on twisting roads can be thrilling. Summing up our experiences with the Avanti, we must admit that we were won over. We didn't think we'd be too impressed but body quality, the power of the R3 engine, handling and other . . .